Regina ‚Äì When the Canadian Light Source, or ‚Äúsynchrotron‚Äù opened at the University of Saskatchewan in 2004, it was hailed as having applications across a wide range of scientific endeavours. One of those current endeavours is –°¿∂ ”∆µ used for oil recovery, by way of foamy oil.

The Petroleum Technology Research Centre (PTRC), based in Regina, is involved in the project.

“The project is a collaboration of the Canadian Light Source in Saskatoon, us, and a researcher in Calgary, Dr. Ian Gates,” said Erik Nickel, director of operations with the PTRC. He spoke to Pipeline Newson Feb. 8.

If you’ve heard that name before, it’s because Gates is the engineering professor who came up with the idea for shipping bitumen in solid form.

“He came to us with the idea of doing a very basic investigation of foamy oil and how it forms. And what is foamy oil? Foamy oil is the result of the degassing of a heavy oil reservoir during production. Imagine if you have bottle of pop that you pop the lid off and it foams a bit. Now imagine if that bottle of pop was instead a bottle of carbonated maple syrup, and what would that look like? It would be much slower and have this shaving cream effect coming out the top. That’s essentially what a lot of the heavy oil production in the Lloydminster area is like.

“Wherever there is cold production, not in the SAGD areas, and where the reservoirs are a little bit thinner, what they try to rely on, to a large degree, is foamy oil. Why we like foamy oil and why it helps in production is there is an increase in volume and an increase in pressure. If you can maintain this foamy oil coming out of the well, you get a larger recovery factor from the reservoir.”

“Eventually the gas drive gives out and you’re trying to suck out ‘flat pop.’ You try to maintain foamy oil as long as you can, or regenerate foamy oil by the injection of gasses of various mixtures,” Nickel said.

“What this research was designed to do was to very fundamentally look at the nature of how foamy oil generates itself at the very start of production, because no small part of this is how it also pulls sand out of the reservoir. Foamy oil is what mobilizes sand. The way these bubbles start to form, under what pressure regime, and how they start to go away is something that was previously unknown.

“Ian Gates’ idea was to essentially have a pressurized physical reservoir model. Essentially this is a vessel full of sand, pressurized with heavy oil and methane under reservoir conditions, then depressurized, and look at it under a CT scanner at various stages in the progression of the bubbles,” he added.

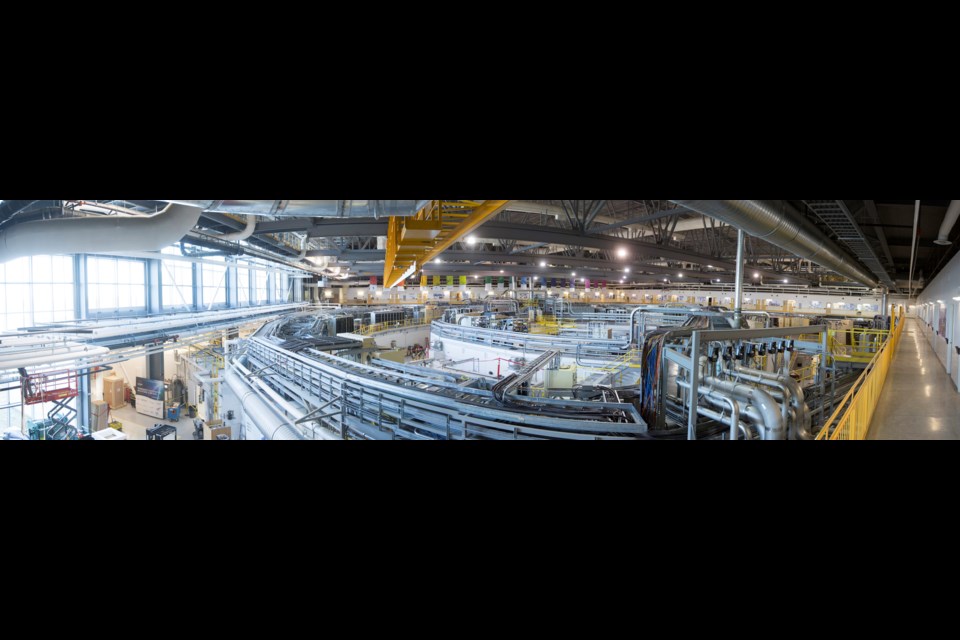

About the time the PTRC received Gates’ proposal, the Canadian Light Source (CLS) contacted the PTRC with information about its biomedical imaging beamline.

Instead of a series of pictures with a CT scan, the synchrotron can basically create a movie of the formation of foamy oil in the reservoir. “What we were able to do is put together a project with the University of Calgary and CLS, funded by Innovation Saskatchewan.”

“We’re looking at foamy oil formation not only in real-time, but microscopically. So we’re seeing where and how a bubble nucleates in relation to a grain of sand. And then, from there, how that bubbles progress to coalescing into bigger bubbles into what we know as foam,” Nickel explained.

The initial tests looked at what rates are best to depressurize a reservoir to maintain the foamy oil as long as possible. Further work on this will look at different mixtures of solvents that could potentially be re-injected to regenerate foamy oil, and the consequent production. Carbon dioxide, methane and propane in various blends are –°¿∂ ”∆µ worked with.

The way these solvents work with heavy oil is a large part of the PTRC’s other research projects. “Looking at it in this microscopic, real-time way with this X-ray invisible core holder is really novel,” Nickel said.

This is one of the Canadian Light Source’s first forays into working with oil and gas, he noted.

Two tests had taken place in the summer of 2018. The first involved glass beads and a glycerin-like substance to approximate heavy oil, as it took some time to get approvals to use actual methane-charged heavy oil. The second test was with real methane and heavy oil in a sandpack. An eventual goal will be to use real core in a subsequent test.

The funding for the project came from HORNET, the Heavy Oil Research Network, and was topped up with additional funds from Innovation Saskatchewan

So what did PTRC find out so far?

“The way the bubbles coalesced happened in an unexpected way,” Nickel said. “The researchers were quite excited about it. It allowed them to form a kinetic model. Now they can apply it to a reservoir simulator. That’s where the real reservoir rocks come in, in a computer sense, and a computer is used to model the optimal rate to depressurize a heavy oil field.”

Commercialization of this knowledge would come from presenting this to the heavy oil producers in the area, most of which are members of the Heavy Oil Research Network (HORNET). It will be up to those companies to decide when and how to implement these findings into the field. Ã˝Ã˝Ã˝

Ã˝

Ã˝