Estevan – Artificial Lift Werx Ltd., or ALX, is now working on bringing incomplete pumpjacks to life, and will soon be building brand new ones in Estevan.

The company was incorporated in April by Dave Heier. This is a rebirth of the company. He started a private placement to raise money. Realizing there wasn’t an appetite in the industry, he took a different route and got bank financing through the Business Development Bank of Canada.

“I’ve got substantial financing in place. I went to the BDC, they’re very pro business,” he said. “I was surprised. They advertise the hell out of it. They say they’re pro business. And they have a mandate to help new businesses, and they came through. They really vet the application to every last detail.”

“Now we’re starting to resurrect some of the old, new inventory. I can put together about 30 units from the inventory that was left over from early days, from 2006. The technical term is new old stock. So we’re going to go through, re-sandblast, and start over. Most of the parts that rotates are going to be all brand new.

“That’s the first kick of the cat.

“I sold ALX in 2013. I got it back.

“The deal went sideways. I finally reacquired it in 2017,” Heier said.

The first goal is to get the new old stock out the door. But the next units, all new, will incorporate a new drive for which he’s in the process of applying for patents. He can’t say more than that.

“Let’s just say the box is more efficient. The pumpjack overall will be safer. The brakes will be positive. The efficiencies, using proprietary drive programming, may save up to 50 per cent power usage,” Heier said.

The design will include a proprietarily programmed variable frequency drive (VFD) made exclusively for ALX. The pumping units will be sold with VFD-only. The pump off programming, gas locking and other problems will be dealt with by the programmable logic controller (PLC) within the VFD.

“The program senses loading and crankweight positioning through a proprietary system,” Heier said.

“It’s going to be epic!” he exclaimed with a laugh.

There isn’t a name for the new jack yet. It’s not likely going to be ALX 2.0, as this will be the new design going forward. “I’m not going to be making conventional jacks anymore,” he said.

After the new old stock is gone, everything will be newly made.

Heier pointed out there are about 5,000 pumping units coming into North America each year. “I just want sell 200 to 300 per year,” he said of his sales goal.

The current sizes include 114, 160, 228, 320, 456 and 640. In the future, ALX will also design a 912 unit. In the future, only sizes 228 and larger will be made.

The financing is in place, and a patent has been applied for. He’s bringing in inventory of needed components to complete the existing units. He’ll be getting castings and buying beams. “All the fun things.”

Castings come from China. “China owns the casting business of the world. There’s no choice,” he said. “They drove everybody else out of business.”

By and large all of the bases and T-frames are done, as are most of the walking beams. But they were all stopped midstream. -

When the first ALX stopped building pumping units, in 2006, Heier said, “I had over 400 jacks in stock, so we stopped building. The price of oil had a slight crash in 2006. A slight correction. And I was selling jacks all over North America, and it dried up overnight.”

The slowdown lased about six months, but it took until 2009 to get rid of most of those jacks. And then the downturn of 2009 came around.

“We were never able to re-kickstart manufacturing, until 2019” he said.

Over 700 ALX jacks were built, and they went to work in every producing province and state in North America. “And they have a good name,” he said.

“There’s zero pumpjack manufactures of any consequence left in North America. There’s some small guys. They’ve all gone to China. Weatherford, HG (Schlumberger), and GE (Lufkin) are the major players now,” he said.

Asked what he’s doing different, he said, “I’ve got a game-changer for my drive. Pumpjacks haven’t changed much since the 1940s.”

“Big corporations always make mistakes. They leave room for the little guy. They either can’t service a person, or tick them off, or they’re just too big to change. I can change quickly. I can do whatever the market wants.

“I’m going to be priced the same, if not higher, than everybody. My drive isn’t cheaper. But in the long run, your maintenance, and your power bill, will pay the difference, and of course, increased production. Lower maintenance, lower power bill, increased production.”

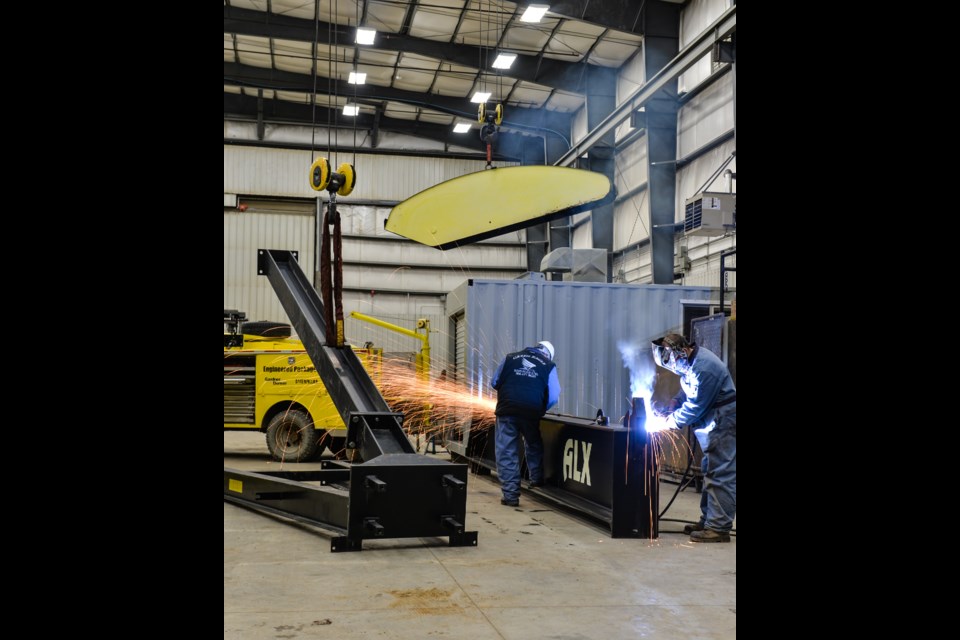

The structural steel they purchase will be laser-cut or plasma-cut elsewhere. Heier said, “But all assembly, all welding, is done here in Estevan.”

The swift drop in oil prices since early October prices has given ALX a bit of a reprieve. He wanted to be further ahead than where he is now. “I was gearing up for $80 oil, thinking I’m going to have a great opportunity. I’m about 8 months slower than I expected to be. I’m quite confident that, this time next year, we’ll be at $80 or $100. That’s the way the world goes. The Saudis won’t allow it to stay down. They want to do an IPO on Aramco. That’s the future of Saudi Arabia,” he said.

“I’m okay with the timing.”

“Our problem, right now, is only in Canada. There’s no problem anywhere else. They’re all ramping up at $50 oil.”

The manufacturing is С����Ƶ done contractually through Waterflood Production Systems (WPS). Heier used to own Waterflood, but sold to Harvey King several years ago. He acts as general manager for WPS.

“I’m taking their highs and lows out of their manufacturing, and I can supplement it with my own employees, in his shop. It’s a two-way street. If he gets behind, my guys can help do his stuff. I think it will benefit both of us.

“It’s a temporary basis. It could be two to three years. I have 11 acres, back with ALX,” Heier said.

Kresten, his son, is general manager for ALX. Heier said, “I hope to have three to six people next year, and to utilize three to six people from waterflood. The long-term goal would be to have a purpose-built shop and 20 to 40 people working.”

Getting there in three to four years is his goal. “It’s my last hurrah,” he said. “I’m doing it as a legacy to hand down to my children.”

“I grew up in Estevan my whole life. Estevan deserves some manufacturing stability, because who knows what’s going to happen with coal and the power plants. I think there’s a lot of good people here, and staff to be had.”